| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

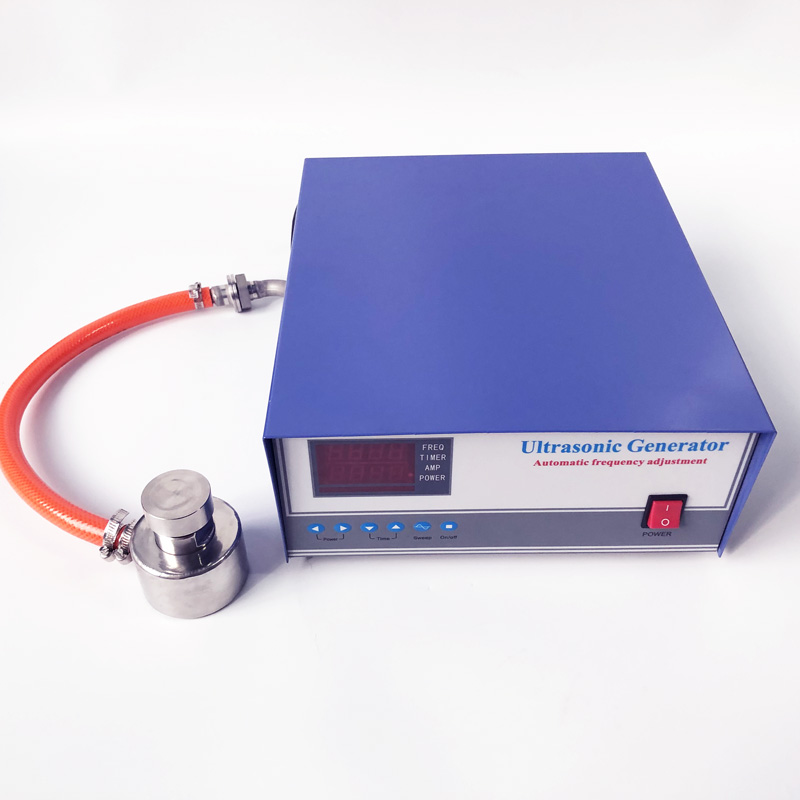

Brand Name : oursultrasonic

Model Number : ARS-ZDHNQ33

Certification : ce and fcc

Place of Origin : china

MOQ : 1pcs

Price : 55

Payment Terms : T/T, Western Union

Supply Ability : 10000

Delivery Time : 3-5 days

Packaging Details : Paper packaging

power : 100w

frequency : 33khz

material : Stainless steel

current : 110V or 220V

name : ultrasonic vibration transducer

application : Fine powder

diy ultrasonic vibration transducer for diy ultrasonic vibrating screen

1. The number of screening meshes selected by ultrasonic vibration screening enterprises does not match the size of screening materials, which means that the required sieve mesh aperture is too small, so it must affect the penetration rate, and the appropriate sieve mesh aperture should be selected.

2. The position of the outlet and outlet of the ultrasonic vibration screen is too high, which will cause the screened qualified materials not to be discharged in time, and lead to the accumulation of material on the screen surface. It should be adjusted to an appropriate height.

3. Ultrasound vibrating screen operators add a large number of screening materials at one time during the operation of the screen machine, which will inevitably lead to material accumulation, and may even cause damage to the screen. So the rocking screen materials should be added evenly, and not blindly in order to increase the screening output. That is the reason. This may be a mistake many users often make in the process of using. In order to ensure that the working state of the ultrasonic vibration screen is good, the screening efficiency and the running state of the equipment should be checked regularly. Make the clearance rate of the sieve hole more than 80%; check whether the rubber ball is worn out, replace it if necessary, and the reason of surface accumulation to maintain the sieve mask has enough self-cleaning ability.

General vibrating screen and linear vibrating screen are materials for screening large parts. However, the ultrasonic vibration screen can screen ultrafine powder. So what's the principle? The next edition will tell you. Ultrasound vibration screen can improve the leveling (light contact between powder and mesh) and slip effect of low density powder in gravity sedimentation, the retention or wedging of high density metal in the mesh, and the adhesion effect of electrostatic powder, so as to improve the screening efficiency and screening quality. In general, the pass rate is 50%-400% higher than that without ultrasonic vibration screen. Ultrasound vibration wave (mechanical wave) attached to screen mesh can make ultrafine powder accept huge acceleration of ultrasound, thus restraining factors such as adhesion, friction, leveling and wedging, and improving screening efficiency and cleaning efficiency. The principle is to convert 220V, 50Hz or 110V, 60Hz electric energy into 18-40kHz high frequency electric energy, and then use the supersonic oscillator head mounted on the screen frame to convert high frequency electric energy into mechanical energy, so that the screen surface produces supersonic vibration invisible to the naked eye, so that the superfine powder accepts huge ultrasonic acceleration, so that the material on the screen surface remains suspended all the time, thus restraining adhesion, friction and leveling. The blocking factors such as wedging and so on can achieve the purpose of high efficiency screening and cleaning, and make the screening of ultrafine powder easy. It is especially suitable for users with high quality and fine powder.

| Type | Frequency(KHz) | Input Power(W) | Static Capacity (pF)±10% |

| ARS-ZDHNQ33 | 33KHZ | 100W | 20-40 |

| ARS-ZDHNQ35 | 35KHZ | 100W | 20-40 |

diy ultrasonic vibration transducer for diy ultrasonic vibrating screen

|

|

Fine Powder High Frequency Ultrasonic Transducer Vibrating Screen 33khz/100W Images |